Budigere Cross, Bangalore, Karnataka

- GST NO. : 29AHHPR8177M1ZA

Products

CHEMIX handles specific range of Ultra High Pure Gases to match the need of the niche market of critical applications. CHEMIX High Pure Gases are guaranteed to be free of critical contaminants that can cause instrument interference and chromatographic column degradation. We achieve consistent high-purity through extensive cylinder preparation, marking dedicated cylinder for specific gas service, and statistical Quality Control. Use of CHEMIX pure gases optimize analytical results regardless of application and significantly extend instrument life

CHEMIX Pure Gases are specifically catered to the following needs:

- Carrier & Detector for GC & GC-MC

- Chemical Ionization Pure Gas for Mass Spectrometry

- Elemental Analysis

- Flame Ionization Fuel Gas Mixtures

- Hydrocarbon Feedstock

- Inert Pure Gases For Blanketing

- Instrument Zero Gases

- Mobile Phases for Supercritical Fluid Chromatography & Extraction

- Reaction Chemistry & Chemical Processing

- Thermal Conductivity Pure Gas

Whether you require a Process Gas Mixture or a High Accuracy Calibration Gas Mixture for an analytical application, you can be sure that CHEMIX has the capability and expertise to meet your needs. Here we present a list of pure gases which are our input ingredient. A wide range of customized gas mixtures can be supplied as required. Gas and liquid mixtures are manufactured with in the limit of physics and chemistry from amongst the chemicals listed below.

Contact us with your specific needs, we provide all types of combinations

+91-9945075154

alroysge@gmail.com

Calibration Gas Mixture - more emphatically a degree of measurement - is our prime product. Gravimetric filling method as per ISO 6142 where the components are added sequentially using traceable weights and improvised manometer method as per ISO 6146 are followed. For Analysis, various GC methods and direct analysis methods as per IS, ISO and ASTM standards are used in the laboratory. Laboratory is maintained as per ISO 17025 (NABL). For certification, ISO 6141-2015 is being followed.

MIXTURES TRACEBILITY

All our Calibration Gas Mixtures are delivered with a calibration certificate compliant to ISO 6141. Due to our thorough approach to quality; we are able to trace every mixture back to its original filling data. This data includes identification of cylinders, production process, actual component weights and chromatographic analysis results. Measuring devices like weighing scales and pressure gauges are calibrated against traceable weights and certified master gauges respectively on a regular interval. Furthermore the gas compositions are analyzed traceable to NIST or NPL references.

PREPARATION TOLERANCE

Preparation Tolerance defines the maximum permitted variation between the requested nominal concentration and the actual concentration supplied.

CERTIFICATION ACCURACY

The Certification Accuracy defines the accuracy of the instruments used and method followed for analysis and certification. Standard uncertainty also calculated as and when required.

PRESSURE

Final Pressure of the supplied gas depends on the vapor pressure of the component and its concentrations. We supply at maximum pressure permissible for the particular composition of gases in a given container.

STABILITY

We guarantee the homogeneity of the gas mixtures stable during the particular period of time. Selection of right cylinder and cylinder preparation followed rigorously to achieve stability.

We manufacture wide range of Calibration Gas Mixtures write from two components to multi components mixtures as required by the user.

Names

- 2-Component Calibration Gas Mixture

- 3-Component Calibration Gas Mixture

- 4-Component Calibration Gas Mixture

- Multi-Component Calibration Gas Mixture

Contact us with your specific needs, we provide all types of combinations

MSDS is furnished on request

+91-9945075154

alroysge@gmail.com

While using the Gases either in Process or Instruments, various Gas Handling Equipment play major role. If proper and compatible equipment’s are not used one cannot get the desired results. Therefore we encourage the user to choose right equipment to handle and inject gases into the system.

Chemix Specialty Gases and Equipment is a leading firm in Manufacturing Gas Handling Equipment located in Bangalore. All equipment’s will be manufactured according to the requirements of the Clients.

We have listed down following Gas Handling Equipment

- Gas Pressure Regulator

- Gas Manifold

- Cylinder Change-Over System

- Gas Tubing / Piping

- Gas Control Module

- Point-Of-Use-Regulator

- High Pressure Flexible Connection (HOSE)

- Cylinder Trolleys

- Cylinder Storage

- Gas Cabinets

- Gas Purification Panel

- Gas Flow Meter

- Gas Leak Detector

- Fume Chamber

- Gas Generators

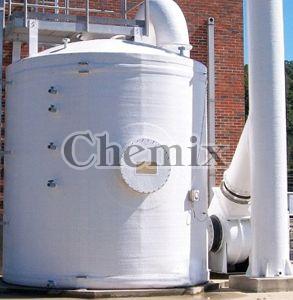

- Gas Scrubbers

Contact us with your specific needs, we provide all types of combinations

+91-9945075154

alroysge@gmail.com